On December 16, 1945, test pilot Lt. Col. Fred J. Ascani and two friends from his days at West Point took off from Bolling Field in Washington, D.C., in an experimental bomber, the Douglas XB-42. The second example built of the unconventional airplane, the XB-42 had set a transcontinental speed record just eight days earlier. Ascani’s flight was supposed to be just a routine test flight, but it proved anything but routine. Within 45 minutes of takeoff, the airplane lay in a crumpled mass in a Maryland field.

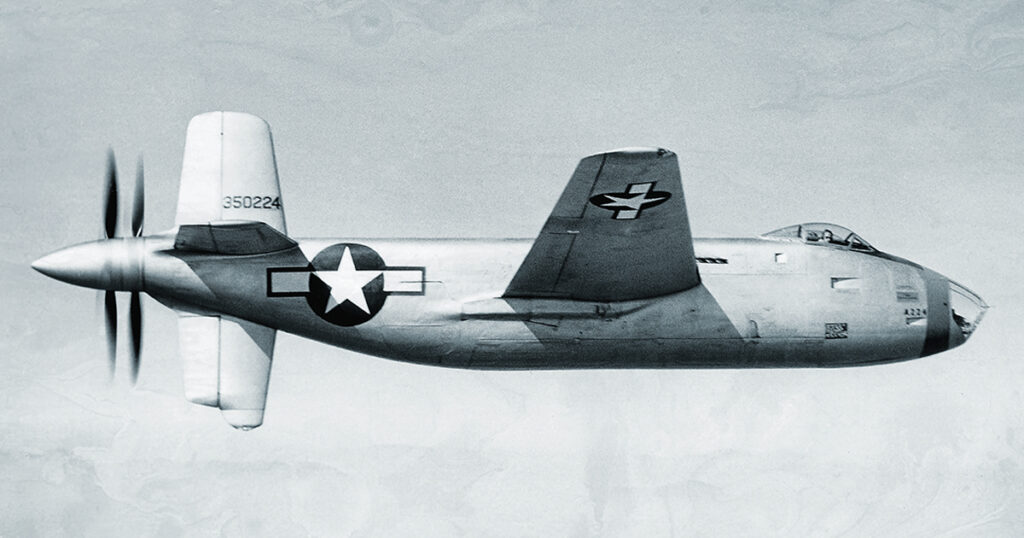

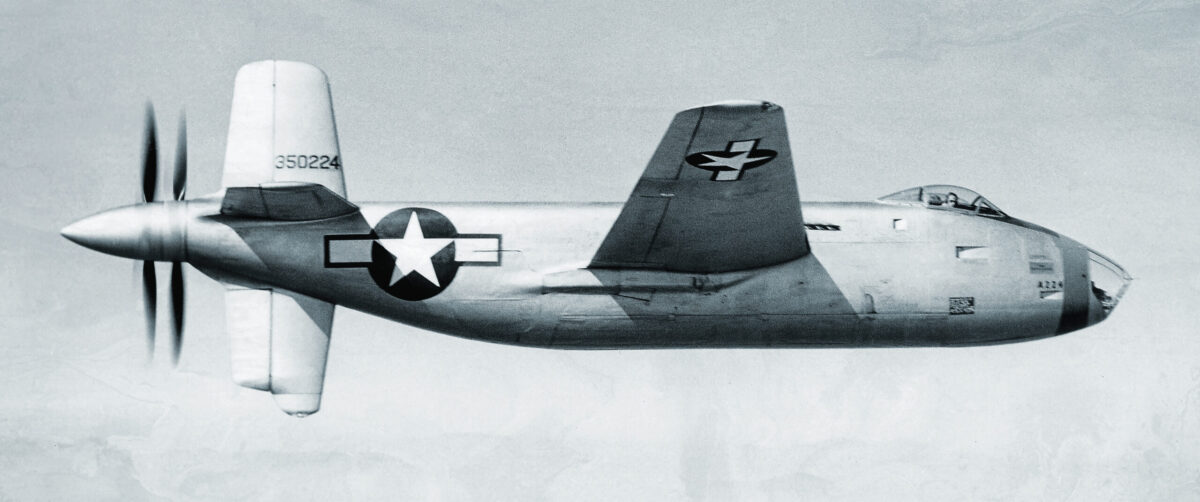

The propeller-driven XB-42 Mix-master and its derivative, the jet-powered XB-43 Jetmaster, were two of many experimental military aircraft tested during the 1940s that failed to meet expectations, despite innovative designs. Nonetheless, both aircraft are notable in aviation history. The XB-42 demonstrated new ideas in streamlining, was the first pusher-type bomber to reach the flight-test stage and, most importantly, led directly to the first American jet-powered bomber to be built and tested.

Douglas developed the Mixmaster as a testbed for a high-speed, long-range bombardment airplane with improved performance, and the company intended to use the project for research on reducing drag and providing better propulsion. To do that, the company decided to develop a medium bomber that met specifications from the United States Army Air Forces (USAAF), including a top speed of 400 mph at a time when USAAF bombers topped out at roughly 300 mph. When Edward F. Burton, Douglas’s chief of engineering, took charge of the project he began with a “clean sheet of paper” rather than attempting refinements of conventional norms. The result was a unique aircraft.

The design Burton settled on, the Model 459, was a mid-wing, all-metal airplane with laminar-flow wings and pusher propellers in the rear of the fuselage. It had a maximum gross take-off and landing weight of 35,000 pounds and could carry up to 8,000 pounds of bombs. By concealing the engines within the fuselage and placing the props in the rear, the design reduced weight and drag that would have come with wing-mounted engines and their nacelles. Drag was estimated to be 70 percent of that of a conventional twin-engine, tractor-type airplane and the maximum speed for the XB-42 at sea level, with a normal fuel load of 650 pounds and a gross weight of 33,206 pounds, was calculated as 344 mph. At 23,800 feet, the first prototype was projected to peak at 410 mph. Its range at 10,000 feet was 1,840 miles, though a reduction in the standard bomb load along with additional fuel would increase the range up to 5,400 miles.

To power the Mixmaster, Douglas chose a pair of side-by-side mounted Allison V-1710s. The liquid-cooled engines were already being used by airplanes such as the Lockheed P-38 Lightning. Each engine had a variable-speed, auxiliary-stage supercharger, automatically controlled by manifold pressure, and turned a coaxial prop. Long shafts extended from the engines to a reduction gear box installed on flexible mounts.

Douglas wanted the props to be independently driven and automatically controlled and to have a reversible pitch feature to shorten the landing distance and prevent too high a speed in a dive. They also wanted the propellers and gear box to be jettisonable so the crew could safely bail out without danger from the rear-mounted propellers. When the XB-42 was in the design stage, no propeller existed with the desired characteristics. The propeller division of the Curtiss-Wright Corporation in Caldwell, New Jersey, in conjunction with Acrotorque Company of Stamford, Connecticut, offered a jettisonable “stop gap” propeller system with electric pitch control and a jettison system while working on the desired “ultimate propeller,” though work on it was eventually canceled.

The XB-42’s pusher system was unconventional for a bomber, and so was its defensive armament. Burton gave the airplane a set of rear-facing twin .50-caliber machine guns and placed them along the trailing edges of the wings. This system eliminated the heavy, manned turrets used on bombers already in service. Although the design made provisions for bomb racks and a bomb sight, the equipment was never included in either prototype.

The USAAF bombers then in service had crews of up to 10 people. The proposed B-42 would have only three—a pilot, copilot/gunner and bombardier. They sat in unpressurized compartments, with the pilot and copilot/gunner side-by-side underneath twin “bug-eye” canopies and the bombardier seated ahead of the pilot in a glazed nose section. The twin canopy arrangement made communications between the pilot and copilot difficult, so the second prototype had a conventional single canopy. The copilot could rotate his seat 180 degrees to operate the gun control panel.

In May 1943, Wright Field’s Aircraft Laboratory in Dayton, Ohio, affirmed the design as “practical for immediate construction” and recommended building at least two prototypes, initially designated as the XA-42 (“A” signifying “attack”). Once the USAAF approved the mockup, it changed the aircraft’s purpose to that of a bomber and redesignated it the XB-42. Douglas later attached the unofficial name of “Mixmaster” because the propellers reminded people of a popular kitchen mixer manufactured by the Sunbeam company.

The first prototype, serial number 43-50224, made its initial flight on May 6, 1944, in Palm Springs, California. Contractor test pilots made 32 flights that led to numerous adjustments before Douglas turned the airplane over to the USAAF on August 16. One significant problem that Douglas encountered was with engine/propeller vibration but eventually engineers developed a new gear box with shock mounts that reduced it to an acceptable level. The bomb bay doors, when open, created even more vibration, though this was eliminated by adjusting the airflow around them.

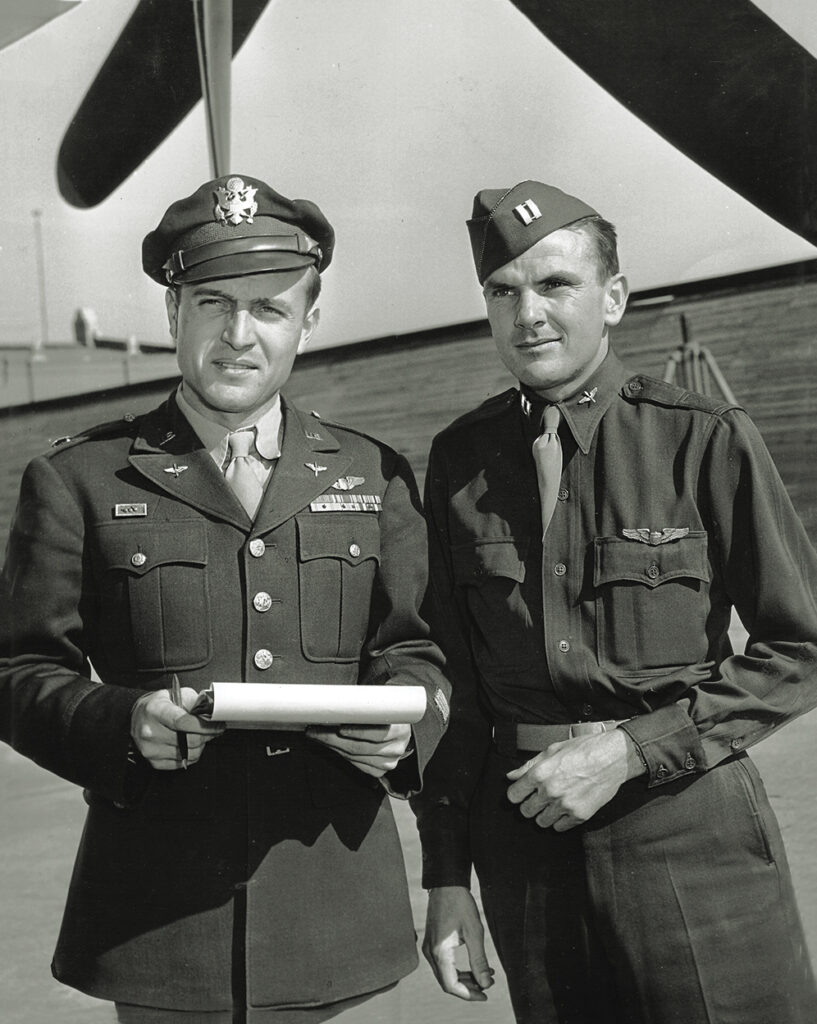

The second prototype, serial number 43-50225, became airborne for the first time on August 1, 1944. It was expected to benefit from a lighter airframe. Douglas test pilots flew it for 70 hours before its official turnover to the USAAF in October. Ascani and Captain Glen W. Edwards then flew the airplane for an additional 48 hours, most of it done at Muroc Army Airfield (later renamed for Edwards after he was killed in the crash of the Northrup YB-49). Even with weight-saving reductions, this airplane fell short of its performance targets. It did not meet maximum speed at altitude nor at sea level, or range with guaranteed bomb load. It met the guarantees for rate of climb at sea level, two-engine service ceiling, and take-off and landing distances over a 50-foot obstacle.

Many of the XB-42’s flight characteristics were quite good. Pilots praised its overall stability, maneuverability and stall characteristics. Despite some issues, including poor controllability at low speeds, Ascani enjoyed flying the Mixmaster, noting it was much quieter than conventional prop-driven planes since the propellers were in the rear.

On December 8, 1945, Edwards and Lt. Col. Henry E. Warden flew XB-42 50225 on an attempt to set a transcontinental speed record. They left Long Beach, California, for the 2,295-mile flight to Bolling. The west-to-east flight path took advantage of the 60-mph jet stream, which contributed to the record-setting average speed of 433.6 mph and an elapsed time of 5 hours, 17 minutes, 34 seconds. Accounting for the jet stream, the aircraft’s true average speed was about 375 mph.

Things did not go as smoothly for Ascani and his two friends eight days later. The flight started inauspiciously; after taking off from Bolling, Ascani had to retract the gear with the emergency system. Roughly 40 minutes later, smoke started to fill the cockpit and the instruments showed the engines were overheating. Then both engines quit in quick succession. Ascani ordered his two passengers to bail out, which they did successfully. Just as he was about to jump, Ascani realized he had not jettisoned the props and “had visions of his friends being mangled” as they went plunging through the spinning blades. He triggered the switch that severed the props and the nearly 400-pound gear box. This made a drastic shift in the aircraft’s center of gravity and the XB-42 plunged into a steep dive. Ascani departed the aircraft at an altitude of 400 feet—just high enough for his chute to fully deploy. He landed not far from the place where the Mixmaster fell, at Oxon Hill, Maryland.

The investigation traced the problem with the landing gear to the hydraulic system. The reasons for the engine failures remained unclear, though fuel starvation was suspected as the cause for the right engine’s quitting. The investigation team did not blame Ascani for the crash.

On March 19, 1946, Edwards was making another test flight in the remaining XB-42 when a rod in the left engine separated and exited through the side of the block. Edwards managed to land safely. At this point, the decision was made to cancel the remainder of the planned test schedule for the propeller-driven XB-42. Instead, the Army wanted to supplement the Allison engines with a pair of auxiliary 1,600-pound thrust Westinghouse 19XB-2 jets within under-wing pods. (Addingjets had been foreseen from the start, so some provisions for them were already present.) Difficulties with the new jet engines, and the fact that demand outstripped supply, resulted in a lengthy delay in getting them, though.

The jet-powered airplane was redesignated as the XB-42A and flew for the first time on May 27, 1947. By then the maximum gross weight had increased to 44,900 pounds, but while the increased drag induced by the add-on jets was noticeable, the airplane’s top speed rose to 487 mph at 16,700 feet. The fuel-thirsty jets reduced the maximum range to 4,750 miles.

Douglas built the XB-42 without expectation of a production order, but the Army did consider acquiring up to 100 photo-reconnaissance versions of the XB-42A. At the time, only three aircraft under consideration for photo reconnaissance met the requirement for very long range. However, the all-jet XB-43 was then (mistakenly) expected to be available in production quantities in 1945 and was considered a better choice for the task.

Design work on the XB-43 began soon after the XB-42 project got underway. By the time the XB-42 was upgraded to the “A” version, both Jetmasters, serial numbers 44-61508 and 509, had already flown. They were powered by a pair of Allison J35 turbojets that provided a total of 8,000 pounds of thrust, and Douglas promised a maximum speed at sea level of 503 mph, and 453 mph at 35,000 feet. With an 8,000-pound bomb load and a speed of 420 mph at an altitude of 40,700 feet, the range was calculated to be 1,440 miles, though reducing the bomb load to 2,000 pounds would increase range to 2,370 miles at the same speed and altitude. Crew size remained at three, with the navigator-bombardier sitting in the nose section and the pilot and relief pilot sitting side-by-side under separate canopies as with the first XB-42.

Development of the J35 engine had been underway since 1943. Begun by GE and then transferred to Allison, the program had been plagued by technical issues. One of the more extreme failures happened during ground testing when a compressor blade in the right-side engine exploded through the engine casing, injuring a technician and damaging the airframe. The J35 also suffered from oil leaks, turbine wheel problems and other issues before it was finally made airworthy. Engine failures still occurred during some flight tests, however.

At one point, the Army considered purchasing 13 YB-43s and at least 50 production versions. This was before World War II had ended and the Allies wanted jet aircraft that could compete with those of the Luftwaffe. Once the war ended in Europe and the first prototype remained mired in delays, the Army’s interest in the B-43 shifted from possible deployment to research and familiarization. Other jet-powered medium bombers in the design stage, the XB-45, XB-46 and XB-47, showed more promise.

The XB-43 was well ahead of other bomber projects by the time it first flew on May 17, 1946, with Douglas test pilots Bob Brush and Russell Thaw on board. This flight lasted only eight minutes, reaching an altitude of 1,500 feet and a top speed of 230 mph. The final contractor flight took place on February 20, 1947, with Brush and James Little as the crew. Further test flights revealed the XB-43 was capable of fulfilling or even exceeding the performance specifications Douglas had guaranteed, with the exception of take-off and landing distances. The plane’s top speed was found to be 515 mph at 5,000 feet at 32,000 pounds gross weight.

The XB-43 still had issues to overcome, though. One of them involved its plexiglass. On the 12th test flight the XB-43 reached 35,000 feet, but the canopies cracked at the high altitude, forcing a redesign. Low temperatures or sudden temperature changes affected the plexiglass nose panels the same way. The problem forced the program to restrict the altitude to 20,000 feet. Finally, engineers reworked the aircraft’s nose using mostly plywood. Pilots also complained that the right canopy obscured their view, so any future B-43s would have received a single, large canopy unit as the second XB-42 had. Additional issues with the Jetmaster included stability problems at high speed and limited center of gravity range. Its unusual characteristics made it necessary to be cautious when instructing pilots how to fly it.

After a lengthy delay for the installation of revised engines, the second aircraft, designated YB-43 (with the “Y” designating a pre-production aircraft), finally made its first flight on May 15, 1947, with Russell Thaw as pilot. This aircraft was transferred to Muroc about 11 months later. After completion of its test flights, the aircraft was assigned to the AMC Power Plant Laboratory to conduct tests with the new GE J47 axial flow jet engine.

The first XB-43 retired from flight testing after becoming damaged in February 1951, and it became a source of spare parts for the remainder of the YB-43 test program. Ultimately, the first prototype, like many surplus and obsolete aircraft, was destroyed as a ground test target for training. The second YB-43 continued to fly until December 1953, when it finally retired with over 300 hours of flight time.

The Air Force donated the XB-42A and YB-43 to the Smithsonian Institution in Washington, D.C., in 1949 and 1954, respectively. In 2010 both were transferred to the National Museum of the United States Air Force in Dayton, Ohio. They now sit side-by-side in the museum’s restoration facility, though neither is currently scheduled for restoration work.

If the XB-42’s test program had somehow progressed at a significantly faster rate, then perhaps a few photo-reconnaissance versions might have flown missions over Japanese territory in the closing weeks of World War II. Faster development of jet engines would probably have resulted in some limited production of the B-43. History did not happen that way, so neither aircraft became a “crate of thunder” for the U.S. Army Air Forces. Instead, they remain quirky examples of an aircraft that had one wing in the propeller era and another in the jet age.