Frank Whittle was born on 1 June 1907 in Coventry, the son of a mechanic. His first attempts to join the RAF failed as a result of his lack of height, but on his third attempt he was accepted as an apprentice in 1923. He qualified as a pilot officer in 1928.

As a cadet Whittle had written a thesis arguing that planes would need to fly at high altitudes, where air resistance is much lower, in order to achieve long ranges and high speeds. Piston engines and propellers were unsuitable for this purpose, so he concluded that rocket propulsion or gas turbines driving propellers would be required.

Jet propulsion was not in his thinking at this stage. By October 1929, Whittle had considered using a fan enclosed in the fuselage to generate a fast flow of air to propel a plane at high altitude. A piston engine would use too much fuel, so he thought of using a gas turbine.

After the Air Ministry turned him down, he patented the idea himself. In 1935, Whittle secured financial backing and, with Royal Air Force approval, Power Jets Ltd was formed.

Following the Wright brothers’ historic flights, the aviation industry experienced rapid advancements, buoyed by concurrent developments in internal combustion engines.

By the late 1920s, aircraft had achieved unprecedented speeds and altitudes, captivating the imagination of many. However, some individuals began to question whether this progress could be sustained without significant technological innovation.

In 1920, the UK Air Ministry initiated a discreet inquiry into the feasibility of utilizing a gas turbine as a propulsion system for aircraft propellers. The initial assessment yielded a discouraging verdict, suggesting that such an engine would be impractically large, heavy, and inefficient.

Nevertheless, in 1926, a more optimistic perspective emerged through a report authored by Dr. A.A. Griffith at the Royal Aircraft Establishment (RAE). This report managed to persuade authorities that further investigation into axial compressor design was warranted.

Consequently, research into this promising field commenced under Dr. Griffith’s guidance in 1927. However, progress faced a setback when funding was withdrawn in 1930 due to the disappointing pace of developments at that time.

Frank Whittle, then an officer cadet in the Royal Air Force, authored a thesis in the initial months of 1928. His thesis, based on meticulous calculations, presented the substantial potential of the gas turbine as a propulsion system for achieving high speeds and altitudes in aviation.

Maximum Speed of 160mph

This remarkable thesis was written during the second year of his cadetship. It’s important to note that during that era, RAF fighters had a maximum speed of 160mph, and their service ceiling was approximately 27,000 feet. However, Whittle’s visionary thinking extended far beyond these limits, envisioning aircraft capable of soaring at 500mph and reaching altitudes of 40,000 feet.

He outlined what we now call a motorjet, which is a conventional piston engine driving an air compressor that supplies air to a combustion chamber. The exhaust from this chamber is used directly for thrust, essentially an afterburner attached to a piston engine-driven air compressor.

This concept wasn’t novel in the industry, but Whittle aimed to show that at higher altitudes, the reduced air density outside would enhance the efficiency of this design. He used the example of a long-range, Atlantic-crossing mailplane to illustrate that this engine, operating mostly at high altitudes, would surpass the performance of standard powerplants.

Whittle believed that to achieve high speeds over long distances, it was necessary to fly at great heights where the thinner air significantly lowers resistance relative to speed.

Among the few apprentices admitted to the Royal Air Force College, Whittle graduated in 1928 at 21, ranking as a pilot officer in July. He stood second in his class academically, earned the Andy Fellowes Memorial Prize for Aeronautical Sciences for his thesis, and was recognized as an “exceptional to above average” pilot.

Despite these accolades, his flight logbook contained several warnings in red ink about showboating and overconfidence. His risky flying in an Armstrong Whitworth Siskin led to his disqualification from the end-of-term flying contest.

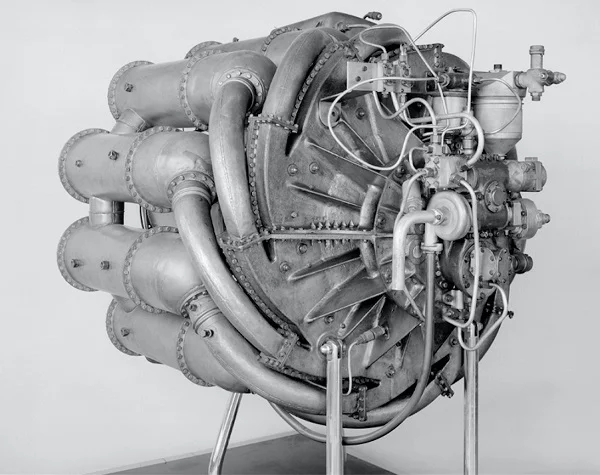

Development of the Turbojet Engine

After his thesis, Frank Whittle kept working on the motorjet but stopped when he found it would weigh as much as a standard engine with the same thrust.

Read More: The AN-12: A Workhorse of the Skies

He then thought, “Why not use a turbine instead of a piston engine?” A turbine could extract power from the exhaust to drive a compressor, like a supercharger, while the remaining exhaust thrust would propel the aircraft.

On 27 August 1928, Pilot Officer Whittle joined No. 111 Squadron in Hornchurch, flying Siskin IIIs. His reputation for low flying and aerobatics nearly led to a court-martial following a public complaint. Within a year, he transferred to Central Flying School in Wittering for instructor training.

He excelled as an instructor and was chosen for the “crazy flying” routine at the 1930 Royal Air Force Air Display in RAF Hendon. He crashed two aircraft during practice but was unhurt. After the second crash, Flight Lieutenant Harold W. Raeburn angrily suggested destroying all the planes as a faster solution.

Whittle shared his engine idea around the base, catching Flying Officer Pat Johnson’s attention, a former patent examiner. Johnson brought the concept to the base commander, sparking a series of events that nearly led to earlier production of the engines.

In July 1926, A. A. Griffith published a paper at the Royal Aircraft Establishment about compressors and turbines. He revealed that existing designs were inefficient and suggested aerofoil-shaped compressor blades for better efficiency.

His paper proposed the potential for a jet engine but recommended a turboprop instead. At that time, interest was low as most superchargers used centrifugal compressors.

“Impracticable”

In late 1929, encouraged by his commanding officer, Whittle sent his concept to the Air Ministry to gauge interest. Unfamiliar with the topic, they consulted Griffith, the only other expert in the field. Griffith doubted Whittle’s design’s efficiency and highlighted an error in Whittle’s calculations.

Read More: Zveno Project an Incredible Aviation Concept

He also remarked that the centrifugal design was too bulky for aircraft and using the jet for power was inefficient. The RAF dismissed the design as “impracticable”.

Pat Johnson, still believing in the idea, helped Frank Whittle patent it in January 1930. The RAF’s disinterest meant it wasn’t classified as secret, allowing Whittle to retain the rights. Johnson set up a meeting with British Thomson-Houston (BTH), whose chief turbine engineer saw merit in the concept. However, BTH was unwilling to invest £60,000 in development, stalling potential early success.

In January 1930, Whittle became a flying officer. He married Dorothy Mary Lee in Coventry on 24 May 1930, and they later had two sons, David and Ian.

“The Case for the Gas Turbine”

In 1931, he was surprisingly posted to the Marine Aircraft Experimental Establishment at Felixstowe as an armament officer and test pilot for seaplanes. Despite no prior seaplane experience, he enhanced his reputation by flying around 20 different types of floatplanes, flying boats, and amphibians.

Read More: Grumman J2F Duck, Legend and Movie Star

While at Felixstowe, Whittle approached Armstrong Siddeley and their advisor W.S. Farren with his proposal, but they doubted the availability of materials for the high temperatures needed. His turbojet needed a 4:1 compressor pressure ratio, double what the best superchargers offered.

Whittle published papers on superchargers and wrote “The Case for the Gas Turbine”, demonstrating the gas turbine’s efficiency at high altitudes and how range depended on altitude in turbojet aircraft.

Every permanent commission officer was expected to undertake specialist training. Whittle went to the Officers School of Engineering at RAF Henlow in 1932.

Excelling in his entrance exam, he completed a shortened one-year course, achieving Distinction in all subjects except mechanical drawing, where he was praised as a hardworking, original, and suitable candidate for experimental duties.

Frank Whittle, Power Jets Ltd and the £5

While still at Cambridge, Whittle couldn’t afford the £5 renewal fee for his jet engine patent due in January 1935. The Air Ministry wouldn’t pay, so the patent lapsed. Shortly after, in May, Rolf Dudley-Williams, a former colleague from Cranwell and Felixstowe, contacted him.

Williams arranged a meeting with Whittle, himself, and another ex-RAF serviceman, James Collingwood Tinling. They proposed a partnership to raise public funds for developing Whittle’s idea.

Whittle believed his improved concept could be patented, emphasizing its low weight and high-altitude efficiency. This led to filing three provisional specifications for a jet-propelled aeroplane.

The partnership quickly yielded results. In 1935, Tinling’s father introduced Whittle to Mogens L. Bramson, a renowned independent aeronautical engineer. Initially skeptical, Bramson soon became a fervent supporter after reviewing Whittle’s ideas. Bramson then introduced Whittle and his associates to the investment bank O.T. Falk & Partners.

Overwhelming

There, they discussed the project with Lancelot Law Whyte and sometimes Sir Maurice Bonham-Carter. O.T. Falk & Partners specialised in funding unconventional projects that regular banks avoided. Whyte was impressed by the 28-year-old Whittle and his design during their meeting on 11 September 1935:

The impression he made was overwhelming, I have never been so quickly convinced, or so happy to find one’s highest standards met… This was genius, not talent. Whittle expressed his idea with superb conciseness: ‘Reciprocating engines are exhausted. They have hundreds of parts jerking to and fro, and they cannot be made more powerful without becoming too complicated. The engine of the future must produce 2,000 hp with one moving part: a spinning turbine and compressor.’ — Lancelot Law Whyte

Frank Whittle had Special Permission

O.T. Falk & Partners agreed to invest in Whittle’s engine only after an independent feasibility verification. They funded an independent review by Bramson, resulting in the positive “Bramson Report” in November 1935. This led to Falk financing Whittle, setting the jet engine on its path to reality.

On 27 January 1936, the “Four Party Agreement” was signed, forming “Power Jets Ltd” in March 1936. The parties were O.T. Falk & Partners, the Air Ministry, Whittle, and the duo of Williams and Tinling. Falk’s representation on the Power Jets board included Whyte as chairman and Bonham-Carter as a director, with Bramson as an alternate.

Read More: Supermarine P.B.31E Nighthawk Zeppelin Hunter

Whittle, Williams, and Tinling kept a 49% share in exchange for Falk and Partners’ initial investment of £2,000 and the option of another £18,000. As a full-time RAF officer at Cambridge, Whittle became “Honorary Chief Engineer and Technical Consultant”. He received special permission to work a maximum of six hours a week while continuing his post-graduate work at Cambridge.

The Air Ministry, viewing this as long-range research, provided little immediate support. Power Jets had no production facilities, so they partnered with British Thomson-Houston (BTH) to build an experimental engine facility in Rugby, Warwickshire.

Hans von Ohain at Heinkel

By the end of 1936, the prototype’s design was final, and its parts were nearing completion within the £2,000 budget. Meanwhile, Germany was also advancing in jet engine technology with efforts from Herbert A. Wagner at Junkers and Hans von Ohain at Heinkel. Von Ohain, having critiqued Whittle’s patents, had to narrow his own patent scope.

In Spain, engineer Virgilio Leret Ruiz patented a jet engine in March 1935. His plans, initially constructed at the Hispano-Suiza factory, were later secretly handed to the British embassy after his execution by Francoist forces.

Read More: Republic XF-103, a 1950s Advanced Interceptor

Despite delays, the Luftwaffe launched their jet program before the British. German designs, lacking high-quality cobalt for steel alloys, risked overheating.

The Junkers Jumo 004 engines, used in the Messerschmitt Me 262, typically lasted only 10-25 hours. Rapid acceleration could cause compressor stalls or explosions.

Over 200 German pilots died in training, but the Me 262, despite late introduction, was significantly faster than Allied planes and effectively armed, shooting down over 542 Allied aircraft and significantly impacting one bombing raid against the Boeing B-17 Flying Fortresses.

Financial difficulty

In January, when Power Jets formed, Henry Tizard, Imperial College London’s rector and Aeronautical Research Committee chairman, urged the Air Ministry’s Director of Scientific Research to review Whittle’s design.

Griffith received the report for feedback but didn’t respond until March 1937, by which time Whittle’s design had progressed. Griffith, working on his own turbine engine, gave a somewhat positive yet critical review, especially about using jet thrust. The ARC Engine Sub-Committee favored funding Griffith’s project instead.

Read More: Nemeth Parasol Maybe the Strangest Aircraft that Flew?

Despite this setback, Power Jets continued, starting test runs of the Whittle Unit (WU) engine on 12 April 1937. Initially, the WU struggled with fuel injection, causing uncontrollable speed, but by August, Whittle planned a major reconstruction to improve combustion and compressor efficiency.

Falk & Partners provided a £250 emergency loan on 9 July. Though their funding option expired on 27 July, they continued supporting Power Jets with loans. In July, Whittle’s Cambridge postgraduate stint ended, but he then worked full-time on the engine on the Special Duty List.

Official Secrets Act

On 1 November, Frank Whittle, Williams, and Tinling assumed Power Jets’ control. Whittle became a squadron leader in December. Tizard praised the engine, convincing the Air Ministry to fund its development with a £5,000 contract for a flyable version.

However, the contract, subject to the Official Secrets Act, wasn’t signed until March 1938, limiting further fundraising. In January 1938, BTH invested £2,500.

Read More: The Sud-Ouest SO.8000 Narval Strike Fighter

Victor Crompton joined Power Jets as the first employee in December 1937. Due to the work’s hazardous nature, development moved to BTH’s Ladywood foundry in Lutterworth, Leicestershire, in 1938. Testing resumed on 16 April 1938 with a reconstructed WU engine, which catastrophically failed on 6 May.

Nevertheless, it ran for 1 hour and 45 minutes, generating 480 pounds-force of thrust at 13,000 rpm. A new WU engine, featuring ten combustion chambers, began construction on 30 May 1938, leading to lighter, more compact design. Testing of this third WU started on 26 October 1938.

Three Packs a Day

Delays and funding shortages slowed down the project. In Germany, Hans von Ohain had filed a patent in 1935, leading to the Heinkel He 178’s first flight in 1939, the world’s first flyable jet aircraft, powered by the Heinkel HeS 3.

Whittle’s work would likely have matched or surpassed this level if the Air Ministry had shown more interest. By the outbreak of war in September 1939, Power Jets only had 10 employees, and Griffith’s operations at the RAE and Metropolitan-Vickers were similarly small.

Read More: Junkers Ju 288 the Bomber the USA Wanted

Whittle’s smoking escalated to three packs a day, and he suffered from stress-related ailments like severe headaches, indigestion, insomnia, anxiety, eczema, and heart palpitations, with his weight dropping to nine stone (126 lb / 57 kg).

To maintain his 16-hour workdays, he used benzedrine during the day and relied on tranquillisers and sleeping pills at night to sleep. He later admitted to becoming addicted to benzedrine. His temperament grew increasingly irritable during this period.

Fortunate Winds

On 30 June 1939, Power Jets struggled financially but managed to impress Air Ministry officials with a demonstration. Whittle ran the third reconstructed W.U. at 16,000 rpm for 20 minutes without issues. David Randall Pye, the Director of Scientific Research, left the demo fully convinced of the project’s importance.

Read More: The Junkers Ju 287 Had Backward Wings

The Ministry decided to buy the W.U. and lend it back, providing crucial funding. They also ordered a flyable version of the engine, the Power Jets W.1 and W.2, and planned a contract with Gloster Aircraft Company for a test aircraft, the single-engine Gloster E.28/39.

Whittle had already explored transforming the bulky W.U. into a practical design. He aimed to power a small 2,000 lb aircraft with a static thrust of 1,389 lb. The W.1’s designed maximum thrust was 1,240 pounds-force, and the W.2’s was 1,600 pounds-force.

The W.2 was meant for the twin-engine Gloster Meteor fighter, but got replaced with the W.2B, offering 1,800 pounds-force. The W.1X, an experimental version, served as a mock-up for the E.28, and a second E.28 used the W.1A, incorporating W.2 features. On 26 March 1940, Air Marshal Tedder identified the jet engine as a potential war winner, prioritizing its development.

Atomising Burner

In May 1940, Power Jets designed the W.2Y, a “straight-through” airflow engine, longer but simpler. To minimize driveshaft weight, the W.2Y used a large, thin-walled shaft.

In April, the Air Ministry contracted BTH, Vauxhall, and Rover Company for W.2 production lines aiming for 3,000 engines a month by 1942, but Rover ultimately took the contract. Whittle was promoted to wing commander in June.

Read More: The Kamov Ka-22 Was A Hybrid of Helicopter and Airplane

On 19 July 1940, Power Jets switched from trying to vaporize fuel to using the controlled atomising burner in the combustion chamber, developed by Isaac Lubbock of Asiatic Petroleum Company.

Whittle remarked, “the introduction of the Shell system marked the end of combustion as a development obstacle.” The company grew from 25 employees in January 1940 to 70 by September 1940 due to the war effort.

Rover was Approached by Frank Whittle

Work on the W.U. continued, undergoing nine rebuilds to fix combustion issues. On 9 October, it ran again with Lubbock or “Shell” atomising-burner combustion chambers, ending combustion problems and starting intensive development of these new chambers.

By now, Gloster’s first airframe was set to be ready before Rover could deliver an engine. Unwilling to wait, Whittle assembled an engine from spare parts, creating the W.1X (“X” for “experimental”), which first ran on 14 December 1940. Power Jets soon applied for a US patent for an “Aircraft propulsion system and power unit.”

The W.1X engine powered the E.28/39 for taxi tests on 7 April 1941 in Gloucester, briefly lifting off for several short hops. The definitive W.1 engine of 850 lbf thrust ran on 12 April 1941.

On 15 May, the W.1-powered E.28/39 took its first flight from Cranwell, lasting 17 minutes and reaching 340 mph. After the flight, Pat Johnson remarked to Whittle, “Frank, it flies.” Whittle responded, “Well, that’s what it was bloody well designed to do, wasn’t it?”

Read More: The Saunders-Roe SR.A/1 Was a Pioneering Seaplane Jet

Within days, the aircraft reached 370 mph at 25,000 feet, outperforming contemporary Spitfires. Its success attracted Rolls-Royce, Hawker Siddeley, Bristol Aeroplane Company, and de Havilland to gas turbine aircraft propulsion in 1941.

By mid-1941, Power Jets’ relationship with Rover worsened. Rover set up a similar facility at Waterloo Mill near their Barnoldswick factory, working on a “straight-through” combustion chamber and turbine wheel alternative to Whittle’s “reverse-flow” chambers.

They named this engine the B.26, approved by the Directorate of Engine Development but kept secret from Power Jets, the Controller of Research and Development, and the Director of Scientific Research until April 1942.

Frank Whittle Meets Rolls-Royce

In January 1940, Whittle met Dr. Stanley Hooker of Rolls-Royce, who introduced him to Rolls-Royce board member Ernest Hives (later Lord Hives) of their Derby factory. Hooker, leading the supercharger division and an expert in fluid dynamics, had already boosted the Merlin piston engine’s power.

His expertise was ideal for jet engine aero-thermodynamics, focusing on optimizing airflow. Hives agreed to provide essential parts for Whittle’s project. Rolls-Royce also built a compressor test rig, helping Whittle address the W.2 engine’s surging problems.

On 10 December 1941, Whittle suffered a nervous breakdown and took a month off. By the end of January 1942, Power Jets had three W.2B engines, two of which Rover built. In February 1942, the E.28 began flight trials with the W.1A engine, reaching 430 mph at 15,000 feet.

Read More: BV 141 – The Asymmetrical Aircraft

On 13 March 1942, Whittle started redesigning the W.2B, creating the W.2/500. By 13 September 1942, W.2/500’s performance tests showed 1,750 pounds-force thrust at full speed. In October 1941, the Ministry approved building a new factory in Whetstone, Leicestershire.

From 3 June to 14 August 1942, Whittle visited the United States. At General Electric’s Lynn Factory, he reviewed the Type I Supercharger, GE’s jet engine based on Power Jets’ W.1X. GE also planned to build an improved W.2B, named I-16, incorporating W.2/500 features.

1,600 Pounds-Force Thrust

Whittle toured Bell Aircraft and saw the Bell XP-59A Airacomets, twin-engine fighters powered by GE I-A jet engines. This fighter flew in October 1942, a year and a day after GE received Power Jets’ W.1X.

On 11 December 1942, Whittle met with Wilfrid Freeman of the Ministry of Aircraft Production and Air Marshal Linnell. Freeman confirmed transferring Barnoldswick and Clitheroe to Rolls-Royce management. Spencer Wilks of Rover and Hives and Hooker from Rolls-Royce met at the “Swan and Royal” pub in Clitheroe, trading the jet factory at Barnoldswick for Rolls-Royce’s tank engine factory in Nottingham.

Read More: XB-70 Valkyrie – The Mach 3 Superbomber

Testing and production immediately accelerated. By January 1943, Rolls-Royce had logged 400 hours of run time, tenfold Rover’s previous month’s achievement. In May 1943, the W.2B passed its first 100-hour development test at 1,600 pounds-force thrust.

When Rolls-Royce joined the project, Ray Dorey, manager of their Flight Centre at Hucknall Airfield in Nottingham, had a Whittle W.2B engine fitted into the rear of a Vickers Wellington bomber. Vickers at Weybridge carried out the installation.

Frank Whittle Wanted More Efficiency

Whittle aimed to enhance the jet engine’s low-speed efficiency. He explained, “I wanted to ‘gear down the jet’, converting a high-velocity, low-mass jet into a high-mass, low-velocity one. The solution was an additional turbine to extract jet energy, driving a low-pressure compressor or fan to push more air as a ‘cold jet’. This is what we know as a ‘turbofan’.”

The first version was the No 1 Thrust Augmentor, with an aft fan in the main engine’s exhaust. In 1942, GE used the No 2 Augmentor, a two-stage system with external fan blades, in the Convair 990 Coronado. The No 3 Augmentor, or “tip turbine”, had turbine blades outside the fan.

Read More: The Handley Page HP.115, the Concorde Test Bed

The No 4 Augmentor, combined with the W2/700 and an afterburner, powered the Miles M.52 project. Whittle noted, “The first turbofan, with the fan supercharging the core engine, was the LR1 for a Pacific bomber. Its bypass ratio was 2–3.” His main turbofan patent 471368, filed in March 1936, expired in 1962.

Whittle’s innovations sparked a revolution in British engine manufacturing. Before the E.28/39’s flight, most companies had begun their research. In 1939, Metropolitan-Vickers started an axial-flow turboprop, later re-engineered as the Metrovick F.2 jet. Rolls-Royce initially copied the W.1 to make the WR.1, but stopped after acquiring Rover’s efforts.

In 1941, de Havilland began a jet fighter project, the Spider Crab (later Vampire), with Frank Halford’s Goblin engine. Armstrong Siddeley developed a complex axial-flow engine, the ASX, with Heppner, but later modified it into a turboprop, the Python. Bristol Aeroplane Company explored combining jet and piston engines but focused on propeller turbines instead.

Power Jets For Sale

During an E.28/39 demonstration to Winston Churchill in April 1943, Whittle suggested to Stafford Cripps, Minister of Aircraft Production, that the government should nationalise all jet development. He argued that private investors had backed the engine’s development, only to lose production contracts to others.

Nationalisation, he believed, was the only fair solution. He even offered to give up his Power Jets shares to facilitate this. In October, Cripps informed Whittle that he planned to nationalise Power Jets alone.

Whittle felt he influenced this decision, but Cripps had already been considering the best way to sustain the jet programme and utilise Power Jets’ expertise in a government-owned research centre.

Read More: Handley Page HP.42 “Giant British Airliner”

In January 1944, Whittle became a Commander of the Order of the British Empire. By then, he had risen to group captain from wing commander since July 1943. Later that month, the Ministry offered £135,500 for Power Jets, which was reluctantly accepted after the Ministry rejected arbitration.

Whittle, having offered his shares for free, received nothing, while Williams and Tinling each got nearly £46,800, and other investors tripled their original investment. Whittle personally objected to Cripps about the nationalisation process but couldn’t change the outcome.

Read More: Britain’s Grand Slam was the Heaviest Bomb of WWII

The final agreement was reached on 28 March, turning Power Jets into Power Jets (Research and Development) Ltd, with Roxbee Cox as chairman, Constant from RAE as Head of Engineering, and Whittle as Chief Technical Advisor. On 5 April 1944, Whittle received just £10,000 for his shares.

From the end of March, Whittle spent six months in hospital for nervous exhaustion and resigned from Power Jets (R and D) Ltd in January 1946. In July, the company merged with RAE’s gas turbine division, forming the National Gas Turbine Establishment (NGTE) in Farnborough. Following Whittle’s lead, 16 Power Jets engineers also resigned.

Later in Life for Frank Whittle

In 1969, Whittle received the Tony Jannus Award for his significant contributions to commercial aviation.

His marriage to Dorothy ended in 1976, and he then married American Hazel S. Hall. Whittle moved to the US and, in the following year, became NAVAIR Research Professor at the United States Naval Academy in Annapolis, Maryland.

He focused his research on the boundary layer before shifting to a part-time professorship from 1978 to 1979. This part-time role allowed him to write “Gas turbine aero-thermodynamics: with special reference to aircraft propulsion”, published in 1981.

Whittle first met Hans von Ohain in 1966 and met him again in 1978 at Wright-Patterson Air Force Base. Initially upset, believing von Ohain’s engine was developed from his patent, Whittle later accepted that von Ohain’s work was independent. They became good friends, often giving joint talks across the US.

After the war, von Ohain told Whittle, “If you had been given the money, you would have been six years ahead of us. If Hitler or Goering had known about your 500 mph experimental plane, World War II might not have happened.”

In 1986, Whittle was appointed a member of the Order of Merit (Commonwealth). He also became a Fellow of the Royal Society and the Royal Aeronautical Society. In 1991, he and von Ohain jointly received the Charles Stark Draper Prize for their turbojet engine work.

Whittle gradually became an atheist. He died of lung cancer on 9 August 1996, in Columbia, Maryland. Cremated in America, his ashes were flown to England and placed in a Cranwell church memorial. Hazel Whittle passed away on 30 July 2007 at the age of 91.