Pierced Steel Planking (PSP), also known as Marston Mat, is a versatile surfacing innovation that played a pivotal role in military operations since WWII. Made from stamped sheets of steel, it is a simple as it gets, but these planks can be used for just about anything.

It was originally made as a quick way of surfacing roads and runways for vehicles and aircraft, but PSP quickly became a duct tape-type tool that could be used to make buildings, roads, fences, doors, slipways, bridges and more.

Background

PSP was designed to solve a critical problem: how to quickly construct durable and reliable runways, roads, and other necessary infrastructure in the varied and often difficult terrains encountered during military operations.

The development of PSP began in the US before the Second World War, driven by the anticipation of the nation’s involvement in global military conflicts. Traditional construction methods for runways and roads were time-consuming, labor-intensive, and unsuitable for the fast-paced demands of modern warfare.

Aircraft typically require paved, grass or gravel runways. The latter two are unsuitable for heavy aircraft, and the former requires extensive construction work, time and materials to prepare. Therefore an alternative was needed for operating in areas that lacked prepared runways.

Engineers and military planners sought a solution that could be rapidly deployed, was lightweight enough to be easily transported, yet sturdy enough to support heavy military aircraft and vehicles. A few different approaches were taken, including 2×4 wooden planks placed on the ground, but they were not successful.

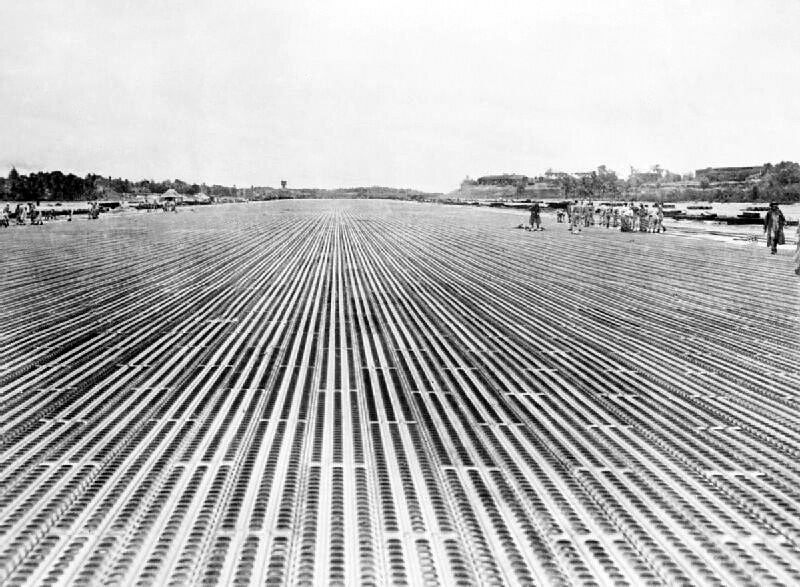

PSP’s design, on the other hand ingeniously addressed the requirements. Made from steel sheets with a series of punched holes (hence the name), the planks could be easily laid down and interlocked edge-to-edge, creating a continuous, stable surface.

The interlocking mechanism was simple yet effective, with hooks running along the edges that slotted into each other, ensuring that the planks could be laid quickly and without the need for specialized tools. Each plank was coated with a corrosion-resistant material, making it durable in a wide range of environmental conditions, from the deserts of North Africa to Pacific islands.

The distinctive holes were added to reduce weight, increase strength and allow water to escape. It was not the first of its kind; other nations had produced similar solutions, but the US’ matting became the Allies’ standard.

As only the sides had the locking hooks, PSP was usually laid in a staggered arrangement, to ensure all planks were connected securely.

The strategic implications of PSP were profound. By enabling the rapid construction of airstrips and roads, PSP significantly expanded the tactical and strategic options available to Allied commanders during conflicts.

It allowed for the quick establishment of forward operating bases, enhanced the mobility of ground forces, and significantly increased the reach and effectiveness of air support. Airbases could be set up in short order as the front lines shifted forward, contributing to the Allies’s overwhelming air superiority achieved during the Second World War.

PSP Usage

PSP provided a quick and reliable solution for constructing runways on varying terrains, whether it be the sandy beaches of Normandy, the jungles of the Pacific islands, or the frozen landscapes of the Arctic. The speed at which PSP runways could be laid down allowed for the swift establishment of air bases, significantly shortening the time required to bring air power to bear against enemy forces.

This capability was instrumental in supporting airborne operations, cargo transport missions, and fighter and bomber operations, directly impacting the strategic balance of the war.

Beyond airstrips, PSP was extensively used for the rapid construction of roads and the repair of existing infrastructure damaged by combat operations. In the fast-moving fronts of both Europe and the Pacific, the ability to quickly move troops, equipment, and supplies was vital.

PSP roads facilitated the mobility of armored vehicles, trucks, and artillery, ensuring that ground forces could advance or redeploy with minimal delay.

Moreover, in the aftermath of battles, PSP was often used to repair or reinforce damaged roads and bridges, restoring critical supply lines and communication routes. The simple hook design on the plank edges made assembly a fast and relatively easy undertaking, and minor replacement or repairs usually ended up requiring only two men to accomplish.

And, when larger repairs were needed, connected planks could actually be rolled up and removed or placed where required.

PSP’s applications were not limited to runways and roads. Its ease of handling and assembly made it suitable for a variety of other military engineering tasks, including the construction of parking areas for vehicles and aircraft, the establishment of temporary buildings, and even the reinforcement of field fortifications.

It wasn’t always the best solution in all scenarios though. For example, it was found to be quite poor on beaches, where waves would lift and dislodge the planks and cover them with sand.

PSP remained in extensive use after the Second World War, seeing major use again in the Korean War. Incredibly, enough PSP had been manufactured by the end of the Second World War to construct nearly one thousand 46 m x 1.5 km (150 ft X 5,000 ft) runways.

However after those wars, the need for urgent, short notice and rapidly deployable airfields were reduced. Thus, the need for PSP also reduced.

Despite that, due to the huge quantities of PSP that was made, it can often be found still in use today in civilian applications. Typically this is in areas that were once near large military installations or activities, such as on Pacific Islands or near old airbases in Europe. They make handy fences or barriers.

PSP Alternatives

A few other alternatives were in use during the Second World War alongside PSP.

Hessian matting was a Canadian design. Also known as prefabricated hessian surfacing, it is made from hessian cloth (similar to burlap) soaked with bitumen. It was primarily utilized as a waterproof covering for runway surfaces, enabling engineers to quickly create a usable runway.

However, the material’s main drawbacks included the need for regular maintenance, especially in areas of aircraft braking and turning, along with a relatively short lifespan. Additionally, installation was not feasible on wet surfaces.

Square mesh track (SMT) was a development by Britain to serve as a quick solution for runway surfacing during the European invasion, suitable only for light to medium weight aircraft. Throughout the invasion, engineers successfully constructed nine airfields using SMT.

While its lightweight and portability were praised, SMT was not very strong when under continued heavy use.

In the later stages of the war, square mesh track, hessian matting and pierced steel planking were used together to create a more robust runway surface. This technique significantly enhanced durability, though its labor-intensive nature meant it was primarily used in locations less vulnerable to enemy air assaults.

Replacement

As mentioned, PSP was not the best solution in all circumstances, so when the urgency of war decreased, newer methods of paving runways were investigated. Any new type had to accommodate newer technologies, such as modern jet aircraft that needed a much smoother surface.

The direct replacement for PSP is AM-2, an aluminium mat without holes, that is reinforced with a honeycomb structure on the inside. It is very strong and smooth, yet very lightweight.

It provides a smooth runway for fighters, and the strength to handle cargo aircraft or bombers.

AM-2 was introduced into the Air Force’s inventory in 1965, and is primarily utilized for the rapid construction of runways, parking aprons, and taxiways. It saw extensive use in the Vietnam War, and remains in service today.