During World War I, German engineer Otto Steinitz had the idea of testing aircraft engines and propellers on railcars. Carl Geissen designed the engine mount, and testing was carried out on a special track at the German Aviation Research Institute (Deutschen Versuchsanstalt für Luftfahrt, DVL) in Berlin. The test car reached speeds of up to 97 mph (140 km/h). After the war, the propeller-driven railcar concept led Steinitz to design a special two-axle car with a mount for an aircraft engine at each end. An enclosed area between the engines housed the crew, passengers, and equipment. Known as the Dringos-Wagen, the machine made a 25-mile (40-km) test run from Grunewald to Beelitz on 11 May 1919. Loaded with approximately 40 people (possibly 35 passengers and five crew), the Dringos-Wagen experienced slow acceleration and a limited top speed of about 37 mph (60 km/h). Interest in Steinitz’s Dringos-Wagen declined after the test, but Geissen continued to design propeller-driven railcars for passenger service into the early 1920s.

Also in the early 1920s, fellow German engineers Kurt Wiesinger and Franz Friedrich Kruckenberg had similar ideas of using propellers to improve and quicken rail traffic. Wiesinger envisioned propelling railcars along the tracks with propellers, while Kruckenberg was considering a streamlined, propeller-driven gondola suspended from a single overhead track as a Zeppelin-on-rails. Kruckenberg’s design was similar to George Bennie’s Railplane of the same period. The pair met in 1923 but soon had a falling out and went their separate ways.

Kruckenberg had studied shipbuilding at the Technical University in Danzig (now Gdańsk University of Technology). One of his professors, Johann Schütte, had partnered with industrialist Karl Lanz to form Luftschiffbau Schütte-Lanz (Airship Construction Schütte-Lanz) in April 1909. After his graduation in August 1909, Kruckenberg joined the firm as a developmental engineer. Kruckenberg was involved with both airship and aircraft constructions while working at Schütte-Lanz, and he was the firm’s chief designer and director of aircraft production during World War I.

After World War I, Kruckenberg left Schütte-Lanz and began to focus on ways to improve rail travel, which is when he met Wiesinger. In July 1924, Kruckenberg partnered with Curt Stedefeld, an associate from university who had also worked for Schütte-Lanz and had founded the Company for Traffic Engineering (Gesellschaft für Verkehrstechnik, GVT) to promote the overhead rail system. Despite a forecasted top speed of 224 mph (360 km/h), the German Ministry of Transportation (Reichsverkehrsministerium) and the German State Railroad Company (Deutschen Reichsbahn-Gesellschaft, DRG) were not willing to offer any financial support. The main objection was the cost of the overhead rail system, which required the support and construction of a completely new infrastructure.

In April 1928, Kruckenberg and Stedefeld founded the Railplane Company (Flugbahn-Gesellschaft, FG) in Heidelberg. The purpose of the new company was to build a propeller-driven railcar for experimentation on existing rail lines to validate the concepts of the overhead rail system. Once FG had demonstrated reliable performance on existing rails, it was hoped that the DRG would be willing to support the overhead rail system.

Around the same time, the DVL was interested in constructing a Propellerwagen to revive the testing of engines and propellers on railcars. Both FG and DVL had petitioned the DRG for the use of a straight, 5-mile (8-km) long, unused track between Langenhagen and Celle. The DRG proposed that the FG and the DVL work together to build a test rig that could be used to test engines and propellers and validate the concepts of propeller-driven railcars.

The DVL Propellerwagen test railcar was completely enclosed with an engine and propeller at each end. The narrow machine was tall with flat sides and had two axles. The rear engine drove its propeller directly via a long shaft, while the front engine drove an elevated propeller shaft via a wide belt. Both engines were six-cylinder, inline BMW IVs that produced 250 hp (186 kW) at 1,400 rpm. The test car weighed around 30,865 lb (14,000 kg) and had a top speed of 109 mph (175 km/h). After operating under its own power for the first time in April 1929, the test railcar eventually made 82 runs that totaled approximately 620 miles (1,000 km). While the DVL test machine did not help advance GVT/BG’s study of aerodynamics, it did provide important information about suspension, handling, and the operation of a propeller-driven railcar.

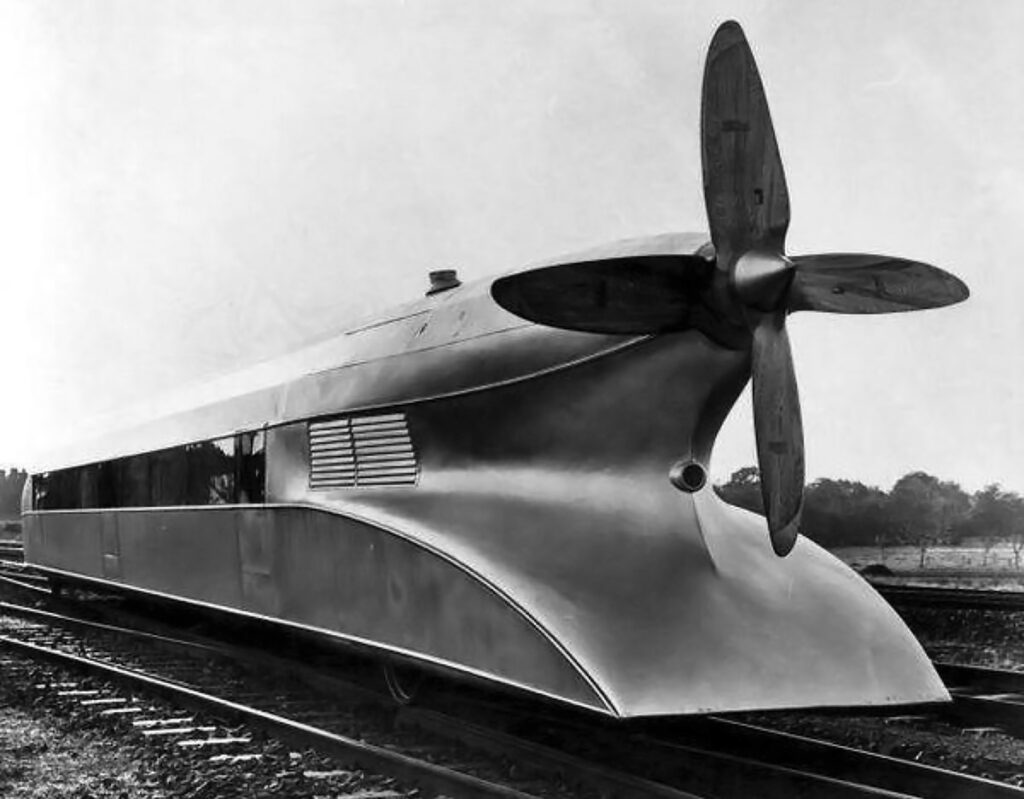

With information from the RVL tests in hand, Kruckenberg and his team compared diesel-electric drives against propeller drives for their railcar. They found that the diesel-electric would cost about 19 times more than the propeller drive and would weigh around 19,842 lb (9,000 kg), compared to 772 lb (350 kg) for the propeller and engine. In June 1929, the design of a streamlined, propeller-driven Railplane Express Car (Flugbahn-Schnellwagen) was laid out and designated Propeller Railcar A (Propellertriebwagen A). This machine was undoubtedly inspired to some degree by the earlier designs of Geissen and Wiesinger. Detailed design work was done in October 1929, and wind tunnel models were tested the following month. Due to its design, construction, and appearance, the streamlined, high-speed railcar became commonly known as the Rail Zeppelin (Schienenzeppelin).

The Rail Zeppelin consisted of a steel chassis with an aluminum truss frame. The engine supports and some other components were also made of steel. The aluminum frame was perforated with extensive lightening holes. The machine was supported on two axles and had a wheelbase of 64 ft 4 in (19.60 m). The axles used rubber ball dampeners for their suspension. Each of its four wheels were 39 in (1.0 m) in diameter. The inner flange of the wheels was made taller than normal to help prevent any possible derailments caused by the machine’s anticipated high speeds. Air-powered friction brakes were used to slow the Rail Zeppelin. An electric drive motor powered the front axle for moving the machine in a limited manner up to 12.4 miles (20 km) and at relatively slow speeds.

Above the rear axle was a single BMW VI liquid-cooled V-12 engine. The BMW VI had a 6.30 in (160 mm) bore and a 7.48 in (190 mm) stroke. The engine displaced 2,797 cu in (45.84 L) and produced 500 hp (373 kW) at 1,410 rpm and 600 hp (447 kW) at 1,540 rpm. The engine’s exhaust was expelled through two vertical stacks. The drive end of the engine pointed toward the rear of the Rail Zeppelin and was elevated seven degrees. A shaft, which was also angled at seven degrees, extended approximately 7 ft 7 in (2.3 m) back to the rear of the machine and turned a four-blade, fixed-pitch Heine propeller made from ash wood. The seven-degree angle on the propeller applied downward force on the Rail Zeppelin and directed the propwash up and away from people on rail platforms. The propeller was 9 ft 2 in (2.80 m) in diameter and was comprised of two stacked two-blade units.

Also attached to the drive end of the engine was a centrifugal fan that circulated cooling air through the engine compartment. Air was drawn in via vents on each side of the Rail Zeppelin and entered a duct at the center of the machine. The air then passed through radiators and was expelled out from the bottom of the Rail Zeppelin. The engine also powered the compressor for the air brakes and two generators for the electrical system. Storage batteries were located in the train’s nose.

The Rail Zeppelin was covered by a streamlined, aerodynamic body. The front, lower sides, and rear of the machine were covered by aluminum sheeting. Windows extended along the sides of the passenger compartment. Due to the expected speed of the Rail Zeppelin, none of the windows opened, and ventilation was provided by forced air. The top of the railcar was covered with fire-proof canvas.

Two drivers sat side-by-side at the front of the train in a raised cockpit, which also had seats for two observers. Passenger compartment access doors were positioned at the front, middle, and rear on each side of the Rail Zeppelin. The 8 ft 2 in (2.5 m) wide and 52 ft 6 in (16 m) long passenger cabin was insulated and had wood paneling. As designed, the passenger compartment consisted of six sections, with each section accommodating four passengers, and a central aisle extended through each section. In addition to the 24-seat configuration, an alternative configuration with bench seating could accommodate 44 passengers. A lavatory was provided at the rear of the cabin. As built, only the forward three compartments were completed, and the rear three compartments held test equipment. The Rail Zeppelin was 84 ft 10 in (25.85 m) long, 8 ft 9 in (2.66 m) wide, and 9 ft 2 in (2.80 m) tall. The railcar weighed 40,962 lb (18,580 kg).

Construction of the Rail Zeppelin started in early 1930 at the DRG repair works in Leinhausen, near Hannover. Without its body, the railcar was mostly complete in August 1930 and moved under its own power with the electric motor. The body was added, and the Rail Zeppelin was completed in September. The first test with propeller power occurred on 25 September 1930. During the first high-speed test, the Rail Zeppelin reached 62 mph (100 km/h) after 66 seconds and 3,232 ft (985 m) of forward travel. The machine hit 93 mph (150 km/h) after two minutes, and the throttle was pulled back just past three minutes at 113 mph (182 km/h).

The initial testing was done in secret and revealed that braking was an issue. Due to the Rail Zeppelin’s streamlining and relatively light weight, light breaking took a long distance, and heavy breaking had a tendency to lock the rear axle. In one instance, the brakes locked the rear axle at 112 mph (180 km/h), and it took 1.2 miles (2 km) for the railcar to come to a stop. A flat spot on the rear wheels about .14 in (3.5 mm) deep was discovered during a quick inspection, but the Rail Zeppelin was still operated up to 87 mph (140 km/h) on its return trip.

On 18 October 1930, the Rail Zeppelin was debuted to the press. Tests continued, some of which involved DRG officials. To test the concept of using a propeller with adjustable-pitch blades, a propeller with reversed pitch was installed, and the Rail Zeppelin was run backward at 37 mph (60 km/h). With the normal forward-thrust propeller reinstalled, propeller braking tests were conducted. The electric motor was used to reverse the train at 28 mph (45 km/h). Then the propeller was engaged, and it alone halted the Rail Zeppelin in 20 seconds. These tests indicated that a fully reversible pitch propeller would greatly enhance the Rail Zeppelin’s braking and improve its safety.

Testing on the isolated track continued until May 1931, when the Rail Zeppelin was operated on the main line. However, no German insurance company would cover the propeller-driven train, and arrangements had to be made with Lloyd’s of London for coverage. The main line test was a 12.2-mile (19.7-km) stretch between Plockhorst and Lehrte. The Rail Zeppelin drew quite a crowd wherever it operated, necessitating a police presence to control the spectators. On 10 May, the machine covered the distance in 10 minutes and reached a top speed of 127 mph (205 km/h).

Testing over a longer distance was needed, so the 160-mile (257-km) route between Hamburg and Berlin was selected. The four-blade propeller was switched in favor of a two-blade unit that would provide a higher top speed at the cost of acceleration. The two-blade propeller was of the same construction as the previous propeller—fixed pitch, wood, and 9 ft 2 in (2.80 m) in diameter.

On 21 June 1931, the Rail Zeppelin left the Hamburg-Bergedorf station at 3:27 AM with a number of observers and crew on board. As the train traveled, its speed continued to increase. However, the track speed limit around many of the curves was 62 mph (100 km/h), which caused the Rail Zeppelin to slow often and accelerate on the straight stretches. Over the 7.5 miles (12-km) separating Karstädt and Dergenthin, the Rail Zeppelin averaged 143.0 mph (230.2 km/h)—a new speed record for passenger rail travel that would stand until 1954. The train arrived in Berlin at 5:05 AM with an average speed of 97.7 mph (157.3 km/h). Along the way, the Rail Zeppelin burned only 48.6 US gal (40.5 Imp gal / 184 L) of fuel, which averaged to 3.3 miles per US gal (1.4 km/L).

After its record run, the Rail Zeppelin was put on display at the Rennbahn-Stadion (now Olympiastadion) railway station in Berlin until 25 June 1930. After the display, the train embarked on a short tour of Germany. The four-blade propeller was reinstalled for the tour, and the speed was kept down to conform with normal scheduled traffic on the line. Once again, the Rail Zeppelin drew large crowds wherever it went. The machine returned to Hannover on 28 June.

A new electromagnetic braking system was installed on the Rail Zeppelin and was tested in March 1932. The system was able to stop the train from 103 mph (165 km/h) in 2,067 ft (630 m). While this was a definite improvement, the distance was still longer than desired. Although the Rail Zeppelin had achieved some level of success, the practicality of such a machine was in question. The train’s long wheelbase caused issues on tight curves, and its ineffective brakes necessitated long stopping distances. The propeller-driven design did not allow coupling multiple units together, and the machine was unable to easily maneuver forward and back for short distances. The large propeller always presented a level of danger to anyone in close proximity to the Rail Zeppelin, and that included passengers waiting on rail platforms.

Kruckenberg and his team took another look at the future of rail travel, and the propeller-driven railcar concept was discarded in favor of a diesel-hydraulic drive that was much lighter than diesel-electric. In May 1932, modifications were started on the Rail Zeppelin to convert the machine to the new power system. The BMW engine and propeller were removed from the rear, and the engine was temporarily installed in the nose of the train until the intended Maybach GO 5 was available. The GO 5 was a 2,588 cu in (42.4 L) diesel V-12 that produced 410 hp (305 kW) at 1,400 rpm. The engine’s exhaust was collected in a central duct that split the center of the cockpit’s windscreen. Via a Föttinger fluid coupling, the engine drove a double-axle bogie positioned under the cockpit. The bogie had a wheelbase of 6 ft 7 in (2.0 m). To accommodate the changes, the train’s nose was elongated, and its cockpit was raised. Its length was increased to 95 ft 2 in (29.0 m) and its weight increased to 62,832 lb (28,500 kg).

The revised Rail Zeppelin was completed in November 1932. The train was tested in early 1933 and reached 87 mph (140 km/h) in under two minutes after traveling 1.5 miles (2,426 m). It was also run at least to 99 mph (160 km/h). However, the DRG had become interested in other trains, namely those powered by diesel-electric engines. The Rail Zeppelin continued to be tested through 1934 and accumulated over 1,491 miles (2,400 km) with its new drive system. The GO 5 engine was finally installed in 1934, and the machine was sold to the DRG. It does not appear that much testing was done with the GO 5 engine. While Kruckenberg and his team continued to design more conventional locomotives throughout the 1930s, the Rail Zeppelin was placed into storage. In 1939, the Rail Zeppelin was scrapped so that its metal could be used to rebuild the German armed forces.

The Rail Zeppelin and its diesel-hydraulic drive served as the basis for the Kruckenberg-designed SVT 137 155, which could accommodate 100 passengers. A single example of the SVT 137 155 was completed in 1938, and the three-section express train set a conventional passenger train speed record on 23 June 1939 at 134 mph (215 km/h). The SVT 137 155 never entered regular service, and it was scrapped in 1967.