WHAT IS A PLANETARY GEAR?

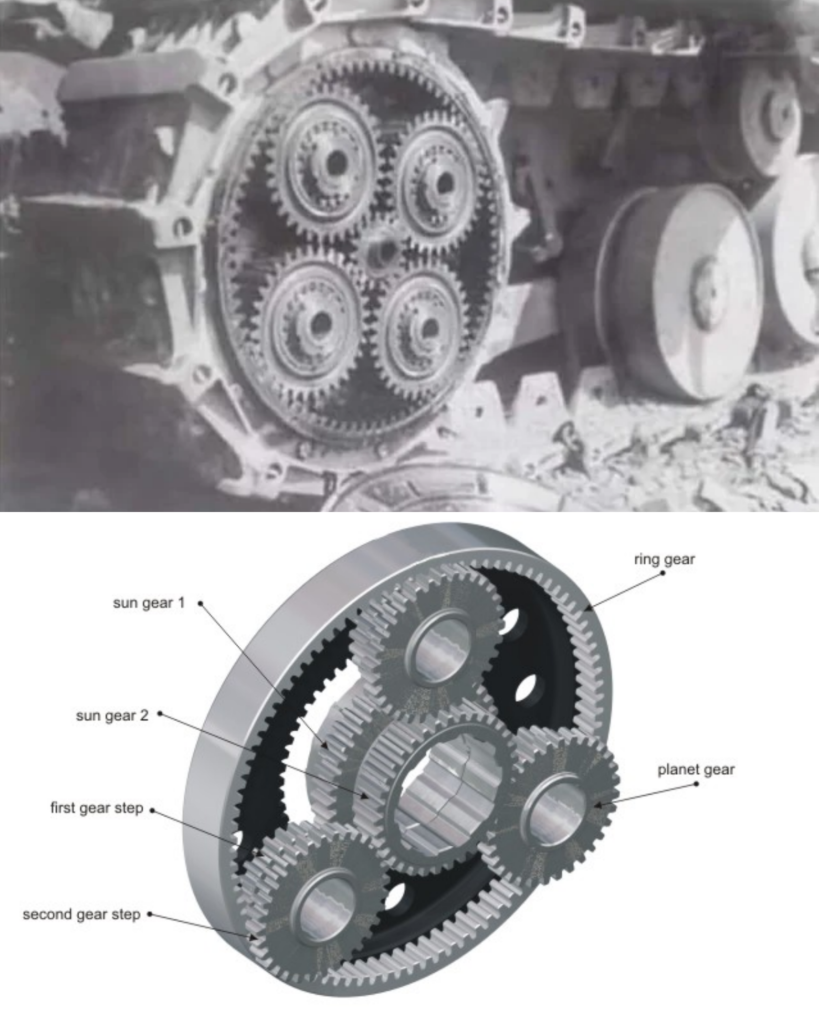

A planetary gear is a type of epicyclic gear system comprised of spur gears. In planetary gearing (also known as epicyclic gearing), a center gear, called a sun gear, serves as the input and driver of the set. Three or more “driven” gears (referred to as planets) rotate around the sun gear within a planetary gearbox. Finally, the planets engage with a ring gear from the inside, which makes an internal spur gear design. Because the planet gears are evenly distributed around the sun gear, planetary gear trains are known to be extremely rugged designs. Another benefit of a planetary gearset is that it is easy to convert to a different ratio by simply changing out the carrier and sun gears.

A planetary gearset uses spur gears that move opposite of each other within the same plane. While spur gears are a more basic type of gear in terms of engineering since they do not utilize specialty angles or cuts like bevel or herringbone gearing, they are complex in the tooth shape design. Depending on the application, this tooth design will determine where the teeth make contact, which then determines the available power, torque, and speed potential of the gears.

Industries And Applications That Use Planetary Gearing

Planetary gear designs are used in a wide range of applications, including automotive and off-road transmissions, wheel drive motors, industrial conveying applications, and others. In fact, even a seemingly simple application like a bicycle uses planetary gearing to power the shifting mechanism. In addition, they can be used as a powertrain between internal combustion engines or connected to electric motors.

Planetary Gearing In Unique Processing Applications

Because planetary gearing is known for its high ratio potential, compact design, and ruggedness, it is ideal for unique applications. Especially in the industrial place, planetary gears are used to power applications in forestry including log decks, debarking equipment, sawing applications, pulp washers, and vacuum filters. Planetary gear drives are also used in sugar cane applications, phosphate industries, steel mills, and asphalt and cement conveyors, mixers, and drums.

Rexnord Planetgear Concentric Inline Gear Drives

Regal Rexnord’s line of Planetgear gearboxes is the premier choice for applications with high shock loads and high torque because a planetary gearbox can handle much higher shock levels than alternative drives. Our design offers up to a quintuple reduction, which allows for efficient higher torque transfer at lower speeds, and in a compact design. In addition, our drives generally see less bearing and seal failure, resulting in longer life. Regal Rexnord stands behind our quality with a 3-year warranty from date of shipment.

Why Use Planetary Gearing?

Planetary gearing is used in rugged applications due to the even distribution of the three planet gears around the sun gear. They are more robust and power dense, meaning that they can handle higher torques and reductions in a smaller, more compact package. They can also handle higher shock loads and higher overhung loads because of the unique self-aligning properties specific to Planetgear.

Planetary gears in planetary gearboxes are more versatile than other gearing because they allow for easy ratio changes. When changing the application used with the gearbox, a user does not have to buy a whole new product since they can simply change the ratio within the planetary design. Specifically within Rexnord’s Planetgear products, our design does not require any special tools or alignment/float settings. The Planetgear also shares components across many of its sizes reducing the amount of inventory needed for safety stock.